Moulds construction

One of our company’s strengths is our own technical workshop, where we manufacture the hot-pressing tools and all the machining and punching equipment.

By manufacturing all the tools and equipment required for the development of your projects ourselves, we guarantee an immediate and targeted response to all requirements. We also carry out modifications and repairs immediately, which significantly reduces the time it takes to manufacture a new product.

The workshop also serves as a training center for our polymechanic apprentices.

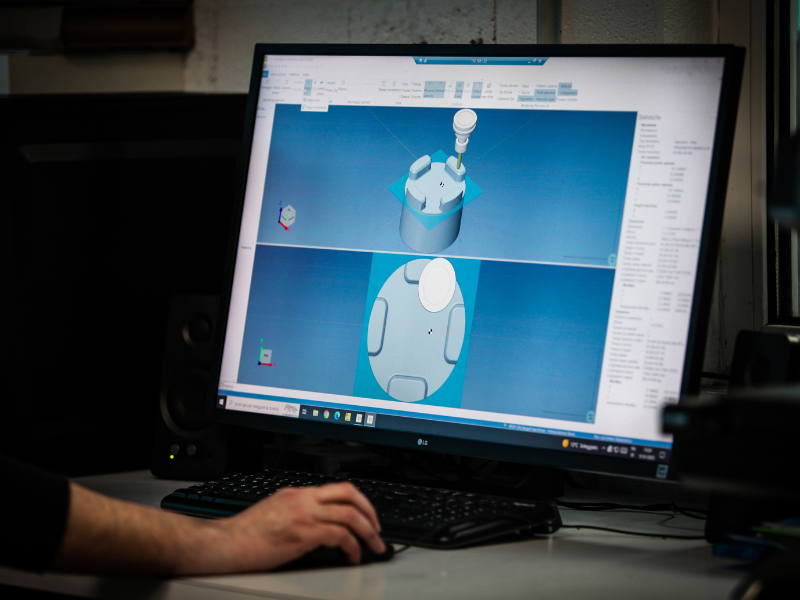

Technical department

The technical office is the heart of our company. This is where all the production processes of the various departments take shape and the methods, critical points and all aspects for more efficient production are defined. By applying the Lean methodology, even production processes that are repeated over the years are constantly improved.

Thanks to our qualified staff, we are at your disposal with a co-engineering service aimed at jointly defining new projects right from the initial phase.

Samples and small series

On request, we can produce samples or small series, even with short lead times, either with a specially designed hot pressing tool or by machining prototypes from solid material using CNC machines.

We can therefore offer an additional service for the prototypes of products that are tested and manufactured before they go into series production. This is done to check the correct functionality.

Quality

The quality of the products we offer our customers has always been important to our company. We have certified measuring systems within the technical office. Quality controls are constantly carried out and intensified when a specific and particular production requires it.

As of 2019, we have a Keyence VR-5200 3D scanner, which is able to perform serial measurements in a short time with a measurement repeatability in the order of hundredths.

Thanks to modern hardness testers, we can issue material hardness certificates on request after internal heat treatment of aluminum and CuNi2Si.

Traceability, flexibility and confidentiality

Our entire production chain is perfectly traceable and defined at every step, from the purchase of regularly certified raw materials to the delivery of the final product. Thanks to specialized software, we can inform our customers about the status of their order at any time.

Our independence from external companies guarantees us the ability to respond dynamically to all our customers’ needs. Small batches, urgent productions, quick changes to existing products – these are all elements that characterize us and guarantee flexibility combined with a high-quality service.

It often happens that we produce components with very high confidentiality criteria. Thanks to the professionalism of all our employees, we guarantee absolute confidentiality and the protection of privacy. As we are also supported by experts in the security of our IT systems, we can guarantee our company and all our customers the necessary security.